Destiny

Automatic water bagging machine Aquapack 2.2 is designed for packaging drinking water. It is used primarily by water supply companies, which can use it to guarantee the continuity of bacteriologically safe water supplies in the event of a water supply network failure or other crisis situation. Aquapack packaging machines are a practical addition to water safety plans.

Construction and principle of operation

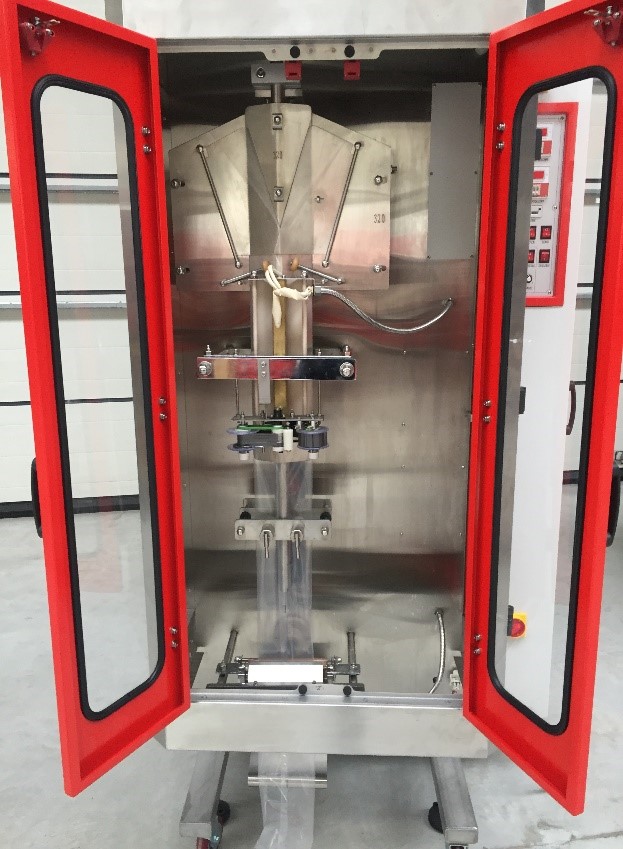

Packer body Aquapack 2.2 It is made of a frame made of sections, encased and powder coated. The front part contains the operator panel and the foil preparation, bag dating and water packaging unit. A conveyor belt for transporting bags with water is attached to the front part. The water preparation unit is located in the side part and the mechanical unit is mounted at the back of the device.

Parcel machine Aquapack 2.2 is made of steel materials, mostly stainless steel, which ensures the microbiological purity of the product. Both drinking water and packaging film are subject to continuous disinfection - UV radiation.

The machine is controlled from the operator panel, while the settings (efficiency and dose) are adjusted manually. The automatic date stamp allows you to determine the production date or expiration date of packaged water.

The packaging film is unwound step by step from the drum via a roller system and fed through a UV lamp for disinfection. The size of the step corresponds to the length of the bag, which in turn depends on the required filling capacity. Between subsequent fillings, the date is entered and then the film is formed into a sleeve using a collar and welded by longitudinal jaws. Before the outlet of the filling pipe, there is a pair of transverse jaws with a profiled jaw, the task of which is to transversely weld the upper bag and simultaneously separate the lower one. After the transverse jaws are spread, the sleeve welded from the bottom is moved by a set stroke size. When the jaws are pushed again, the filled bag is welded in its upper part and separated from the sleeve. The cut bag slides onto the slide and from there onto the receiving conveyor.

Quality and durability of packaged water

The device is usually installed at the local water treatment plant or in another suitable place with access to the water supply network that meets the requirements of the Regulation of the Minister of Health on the quality of water intended for human consumption. The shelf life of water packed in plastic bags should not exceed 6 months, and the bags themselves should be stored in a dry, dark and cool room.

Packaging

Water bags can be made of the highest quality polyethylene, which is a recyclable material and can be repeatedly processed into other products. The bagging machine is also adapted to pack in bags made of biodegradable film. Ecological biodegradable and compostable film is produced from bio-raw materials, i.e. polymers derived from renewable raw materials, certified in accordance with DIN EN 13432 and ASTM D6400 (e.g. potato starch). Such film decomposes in the natural environment, can be processed with organic waste in composters and the obtained compost can be used, among others, in agriculture.

Scope of application

Aquapack baggers can deliver potable water bags for:

- occurrence of water supply network failures,

- identification of secondary water contamination in the water supply network,

- occurrence of natural disasters (floods),

- freezing / damage to connections,

- organization of mass events.

Transport of bags

In terms of requirements for the method of transporting water bags, it is only recommended to maintain the proper cleanliness and aesthetics of the packaging, limit sunlight, maintain a cool ambient temperature as much as possible and shorten the delivery time to the recipient as much as possible. To maintain the above conditions, the most appropriate are blue boxes made of polyethylene with external dimensions of 600x400x2000 mm. Although it is not required, it is recommended that the boxes have an appropriate PZH certificate. Such packages can be transported in ordinary delivery vehicles as well as in special trailers, e.g. Proffico Aquatrans having special drawers with latches enabling their safe transport and thermal housing.

more information can be found in the pdf file.

Aquapack 2.2 drinking water packaging machine

Product

Sale options

purchase

service

Ask for details

Contact a specialist dedicated to this product

Małgorzata Stefańska

tel. +48 538 306 407

e-mail: malgorzata.stefanska@proffico.com

Ewelina Wyganowska

tel. +48 532 781 270

e-mail: ewelina.wyganowska@proffico.com

References

Aquapack series packaging machines have been installed in the following water supply companies:

Municipal Waterworks in Radom, PWiK in Starachowice, ZWiK in Ciechanów, KGK in Kozienice, MPWiK in Rzeszów, PWiK in Mińsk Mazowiecki, MPWiK in Warsaw, ŻWiK in Żagań, PWiK in Wyszków, PWiK in Gliwice, PWiK in Węgrów, Municipal Waterworks in Chojnice.

Case study