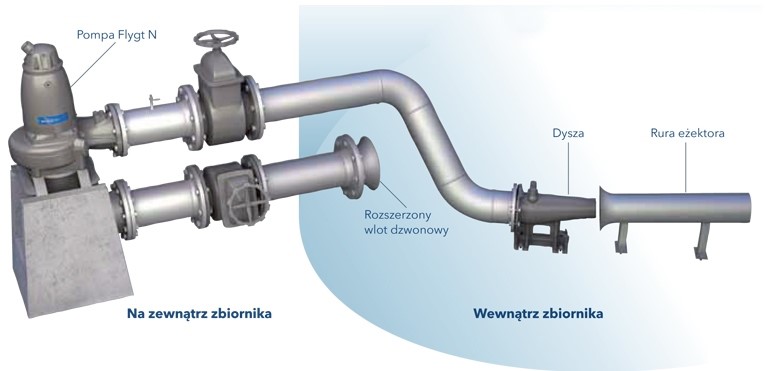

Flygt jet mixers combine patented Flygt N-pump technology with an innovative ejector assembly to create a unique, highly efficient and effective mixing system. They are the ideal solution for demanding wastewater and sludge applications where dry installation is preferred.

Combining two Flygt innovations into one effective jet mixer system provides the highest efficiency at the lowest possible operating cost. The use of jet mixers creates a strong mass flow that minimizes solids settling and the consequent formation of sediment deposits.

This extremely versatile, floor-mounted system provides adequate mixing performance in partially filled tanks with low liquid levels, as well as in fully filled tanks.

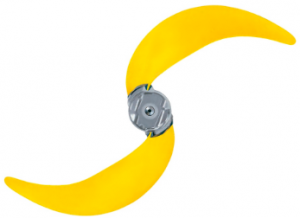

Flygt N-pump

Unlike conventional pumps handling solids that experience efficiency loss due to clogging, Flygt pumps maintain their efficiency regardless of the fluid composition. This is called constant efficiency. This is possible thanks to the patented self-cleaning hydraulics of the N-pumps, which include swept-back, swept-back impeller edges, a widening discharge groove and an integrated guiding pin.

In addition to exceptional resistance to clogging, patented N-pump technology handles municipal sludge up to 8% dry solids. For abrasive applications, durable Hard-Iron™ hydraulics are available to maintain maximum pump efficiency. Flygt N-pumps are also available in explosion-proof versions.

Unlike conventional dry-installed pumps, Flygt N-pumps feature an electric motor integrated with the hydraulic unit in a single housing (monobloc design). This makes Flygt N-pumps more compact and therefore easier and cheaper to install.

Innovative ejector assembly

The carefully designed, non-clogging ejector assembly consists of a large discharge nozzle and an ejector tube with a specially shaped inlet. The nozzle outlet diameter is designed to pass solids the same size as the pump passage. The pump generates a primary flow that is fed to the tank via a system of pipes ending with the nozzle. When this flow is introduced into the ejector tube, a secondary flow is induced from the surrounding liquid. Computer simulation of fluid dynamics clearly shows the interaction between the discharge nozzle and the ejector tube. The primary flow is amplified by the generation of the secondary flow.

Benefits

- maximum mixing efficiency and performance,

- long-term pump efficiency and reduced energy costs,

- compact pump design that does not require a special housing,

- easy access and service outside the tank,

- ability to work at low liquid levels,

- effective treatment of sludge with a concentration of up to 8% dry matter

For more information, please see the pdf file.

Jet mixers

Products

Sale options

purchase

service

Ask for details

Contact a specialist dedicated to this product

Arkadiusz Witak

+48 885 805 502

e-mail: arkadiusz.witak@proffico.com

References

The advantages of the offered mixers are appreciated by: EKO Radomsko Sp. z oo, Sewage Treatment Plant in Sułkowice, Chynów commune, Sewage Treatment Plant in Kutno, Damian Wąsiewski Service and Trade Company, Water and Sewage Company Sp. z oo in Morąg, Solida Radosław Muszyński Sp. z oo Warsaw

Case study