The pumping station can be used to pump various types of media: sewage from industrial plants, domestic sewage, rainwater and drainage. For users of sewage systems using sewage pumping stations, the most important elements are operational reliability and maintenance-free operation of such facilities. These aspects should be taken into account when making the appropriate selection of pumps and other elements, e.g. tank cleaning.

Sewage is a non-homogeneous medium, often containing large amounts of solid sediments or other mineral or organic admixtures, which is not taken into account at the stage of designing and selecting pumping station equipment. After a certain period of operation, the sediments sediment and then the sewage pumping station becomes clogged and does not work effectively. This is accompanied by putrefactive processes that are bothersome for people staying or living near the facility.

Flygt has been using the patented TOP system in wastewater pumping stations since 1995, providing customers with numerous benefits at low investment costs.

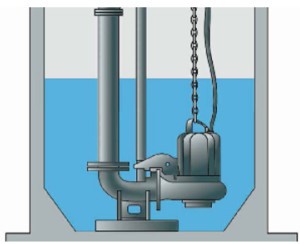

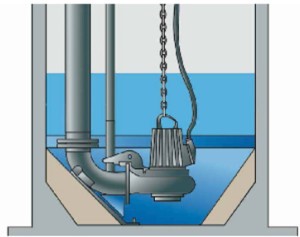

Application TOP bottom inserts reduces the accumulation of solids and sludge on the bottom in two ways. Firstly, the bottom surface of the sewage pumping station is much smaller than standard slopes. The sediments accumulate directly under the pump, where they can be freely sucked in by sewage pumps. Secondly, the patented geometry of the TOP insert ensures the optimization of the sewage flow on the bottom of the pumping station, which leads to the creation of a turbulent flow that lifts the sediments, thanks to which they can be freely pumped out.

Ultimately, we get a sewage pumping station that cleans itself.

TOP insert can be mounted in two ways:

- construction of a new sewage pumping station with a TOP insert,

- modernization of the existing pumping station by "gluing" the insert to the bottom of the existing tank.

Pumping station with bottom insert TOP provides the user with:

- integrated design for self-cleaning,

- minimizing the accumulation of sediment,

- tested and confirmed operation in hundreds of applications in Poland,

- easy to introduce into existing pumps,

- ease of installation.

Thanks to the use of hydrodynamic flush valve the pumping station is cleaned automatically.

If grease and sediments are allowed to accumulate in the sewage pumping station well, the effect does not have to be just an unpleasant smell. Level regulators may become contaminated, which leads to a deterioration in the operational efficiency of the entire pumping station and, in extreme cases, may stop its operation and lead to failure. Therefore, regular removal of sediments is very important. If these activities are performed by personnel using mechanical methods, one must expect downtime of the facility and, above all, high costs.

How does a hydrodynamic valve work?

When the pump starts, the valve opens for about 20 seconds, causing a strong jet of water to be ejected, which flushes away all sediment. The sewage sludge is then sucked up by the main pump. The flush cycle is an integral part of the pump cycle, and therefore flushing occurs every time the pump is started.

APF Driver works in parallel to the main controller, ensuring the removal of scum from the pumping station. This controller periodically extends the pump operation below the set minimum level until the first air is sucked in, causing the pump to switch off (change in current intensity). Thanks to this procedure, the pump sucks in scum along with all floating parts and grease in the last phase of its operation, which results in self-cleaning of the pumping station. The frequency of switching the system on can be set in any range depending on the specificity of the sewage (usually this system is started 10 times a day).

For more information, please see the pdf file.

Normal 0 21 false false false PL X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:Standard; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0cm 5.4pt 0cm 5.4pt; mso-para-margin-top:0cm; mso-para-margin-right:0cm; mso-para-margin-bottom:8.0pt; mso-para-margin-left:0cm; line-height:107%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri",sans-serif; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi; mso-fareast-language:EN-US;} Normal 0 21 false false false PL X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:Standard; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0cm 5.4pt 0cm 5.4pt; mso-para-margin-top:0cm; mso-para-margin-right:0cm; mso-para-margin-bottom:8.0pt; mso-para-margin-left:0cm; line-height:107%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri",sans-serif; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi; mso-fareast-language:EN-US;} TOP insert

Products

Sale options

Flygt Pumps

purchase

service

Flygt pumps with Concertor system

rent

purchase

service

Ask for details

Contact a specialist dedicated to this product

Arkadiusz Witak

+48 885 805 502

e-mail: arkadiusz.witak@proffico.com

References

Reliable Flygt pumps are used in many sewage pumping stations, including: MPWiK Warszawa, PWK Legionowo, Cyfrowy Polsat, Przedsiębiorstwo Komunalne Nadarzyn, Zakład Usług Komunalnych Sp. z oo in Warka, Austria Juice Group, Sewage Treatment Plant in Sułkowice, MZGK Sp. z oo in Dęblin, PGK in Żyrardów, ZGK Konstancin Jeziorna, State Archives, Tarnobrzeskie Wodociągi Sp. z oo, POP in Mszczonów (main pumping station)

Case study